Your Engineering Partner with Know-How

Providing industrial fabrication and machinery maintenance since 2000

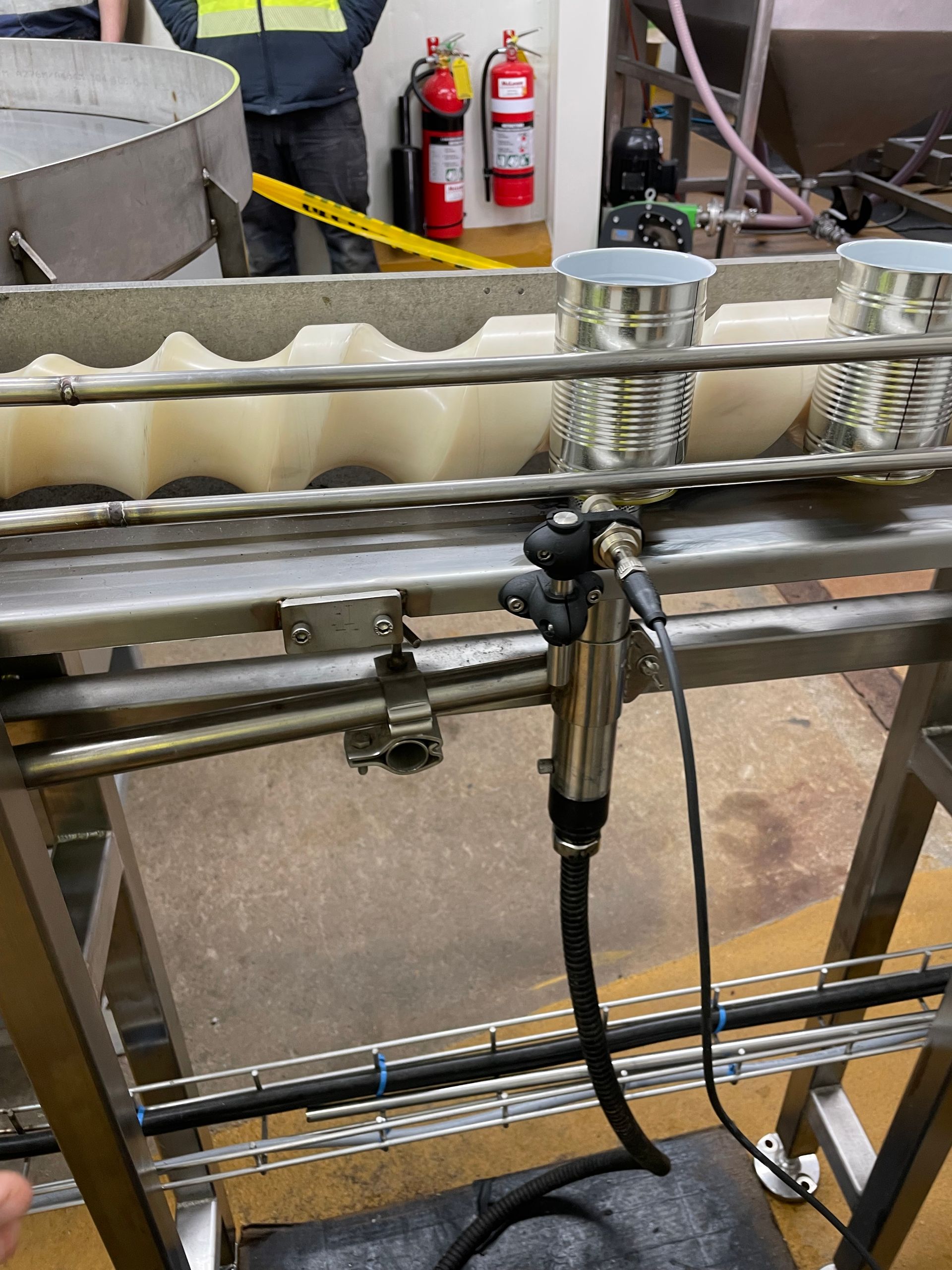

Agnew Food Maintenance Services, Christchurch

Full-service Engineering For Food Industry

We design and build specialised machinery for the food processing industry. Large or small production, Agnew can provide an economic solution to keep your production moving seamlessly.

We manufacture a wide range of spare parts and components too and can commission and install both new or used equipment. We’ll train your operators on safety procedures and how to use the equipment.

We back up every install with regular, scheduled maintenance.

- Design and Fabricate

- Reconditioned 2nd hand Machinery

- Custom Machining

- Maintenance Scheduling

- Breakdown Repairs

Food machinery and maintenance specialists for all kinds of processors, from bakeries, breweries, butchers, canneries and dairy to name a few.

Ensuring the Integrity of Food Making Equipment

We provide sanitary welding standards for food-grade applications. We work to the latest NZ Standards for hygiene & sanitation certification.

We’re experienced in specialised welding for food-grade installations including stainless steel purge welding. Eliminating food contamination from porous surfaces and corrosion or heat stress cracking.

Internal angles are radiused without making burrs or sharps. We create and install seamless sanitary pipeworks and products, making sure they are also easily disassembled for cleaning. Protecting & certifying the integrity of your equipment and its hygienic properties.

Specialised Food Processing Machinery

We design and make specialised machinery for food processing operations.

Manufacturing workable solutions are what we do best, but if need be, we can also import specialised machinery to order. Whatever particular task you seek to automate swiftly and cost-effectively, talk to Agnew Food Machinery Specialists today.

We back up every install with regular, scheduled maintenance.

- Bread and doughs

- Pies, pastries and pizzas

- Cakes, sponges, biscuits and baked goods

- Sauces and soups

- Dairy products

- Meat & poultry small-goods

- Fruit & vegetables

Maintenance & Emergency Repair Service

Keeping your machinery operating safely and efficiently through regular maintenance is key to optimal production. Supporting our clients to achieve this, we provide scheduled maintenance contracts and breakdown service for the industry.

Reduce downtime and help keep machinery safer for employees with our scheduled maintenance program. We take care of the details, allowing you to keep on producing. Talk to Agnew today about a maintenance schedule to keep your operations smooth, safe and compliant.

Machine Reconditioning & Customisation

We’re all about providing the best value solutions for your machinery needs. Keeping capital outlay low, by reconditioning and customising existing machines, makes good economic sense.

We recondition existing machines and motors and can modify and upgrade your existing set-up for greater efficiency and output, without massive upfront costs.

Talk to Agnew today about upgrading & customising for food manufacture machinery.